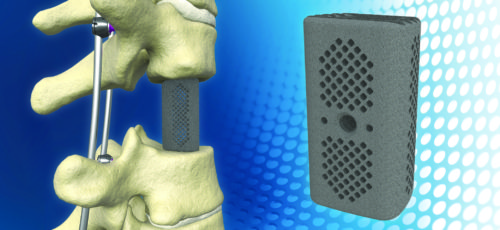

LEESBURG, Va., June 28, 2017 (GLOBE NEWSWIRE) — K2M Group Holdings, Inc. (NASDAQ:KTWO) (the “Company” or “K2M”), a global leader of complex spine and minimally invasive solutions focused on achieving three-dimensional Total Body Balance™, today announced that its CAPRI™ Small 3D Static Corpectomy Cage System has received 510(k) clearance from the U.S. Food & Drug Administration (FDA). CAPRI Small 3D Static is a first-to-market, 3D-printed, FDA-cleared corpectomy cage, and the Company’s third product family to feature Lamellar 3D Titanium Technology™. This clearance marks a milestone for the Company, which provides 3D-printed solutions for MIS, degenerative, and now complex spine procedures. K2M was the first leading spine company to market a 3D-printed spinal implant and offers the most comprehensive portfolio of 3D-printed spinal devices.

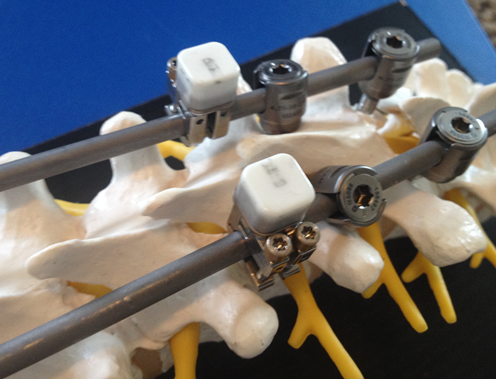

CAPRI Small 3D Static provides a surgical solution for stabilizing the thoracolumbar spine (T1 to L5) in cases of vertebral body resections resulting from trauma or tumor. Its porous structure and rough surface architectures are designed to allow for bony integration throughout an implant. The system’s lordotic options help support the anterior spinal column with the goal of achieving sagittal balance.

“CAPRI Small 3D Static provides me with a corpectomy cage that incorporates the Lamellar 3D Titanium Technology to treat patients with complex pathologies,” said Michael Finn, MD, a neurosurgeon and assistant professor in the Department of Neurosurgery at the University of Colorado. “The incorporation of pores into the endplates increases the surface area for fusion and presents the potential for bone to grow into the corpectomy cage.”

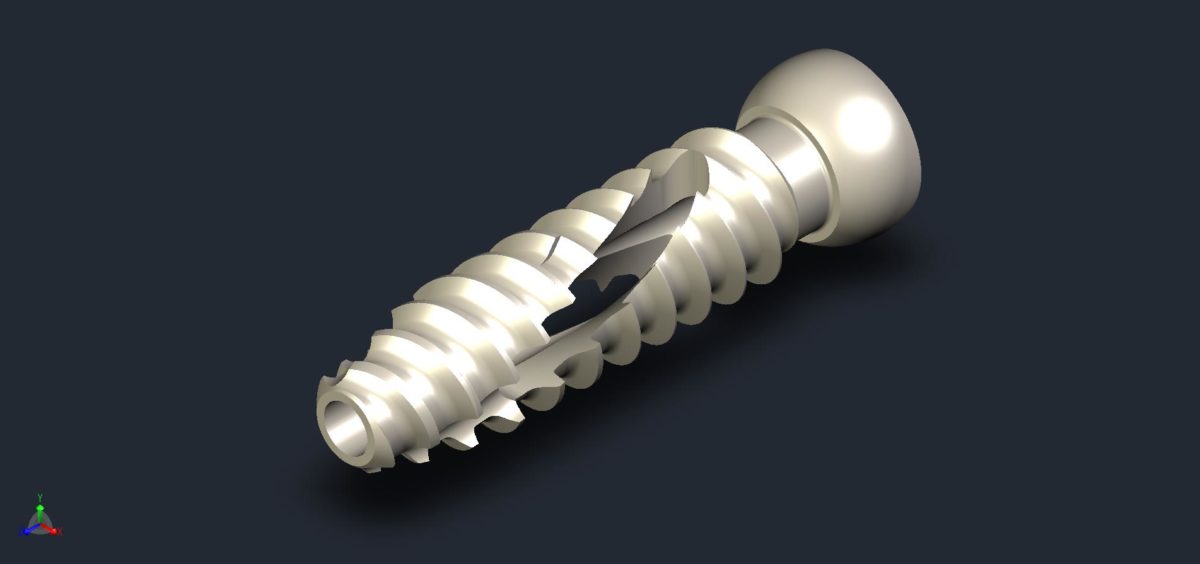

K2M’s Lamellar 3D Titanium Technology uses an advanced 3D printing method to create structures that are impossible with traditional manufacturing techniques. Starting with a titanium powder, the CAPRI Small 3D Static corpectomy cages are grown through the selective application of a high-energy laser beam, incorporating complex internal geometries and rough surface architecture that pre-clinical data have associated with bone growth activity. Lamellar 3D Titanium Technology incorporates a porous structure along with rough surfaces to allow the potential for bony integration throughout the cage.

“K2M’s excellence in 3D-printing innovations allows us to aid surgeons in treating spinal pathologies across MIS, degenerative, and now complex spine segments,” said K2M’s President and CEO Eric Major. “Today, we are excited to introduce CAPRI Small 3D Static, a 3D-printed surgical solution for correcting complications from trauma or tumor in complex spine cases. This is our third product family—which already includes the CASCADIA™ 3D family of static interbodies and the MOJAVE™ PL 3D Expandable Interbody—to feature Lamellar 3D Titanium Technology.

“K2M is leading the way in 3D spinal solutions—as evidenced by our comprehensive Balance ACS™ platform and our market-leading 3D-printed portfolio—and our disruptive technologies provide surgeons with both diagnostic and therapeutic solutions to treat patients around the world,” added Major.

Balance ACS (or BACS™) is a comprehensive platform applying three-dimensional solutions across the entire clinical care continuum to help drive quality outcomes in spine patients. BACS provides surgical solutions focused on achieving balance of the spine by addressing each anatomical vertebral segment with a 360-degree approach of the axial, coronal, and sagittal planes, emphasizing Total Body Balance as an important component to critical success.

For more information about the CAPRI Small 3D Static Corpectomy Cage System featuring Lamellar 3D Titanium Technology, as well as all of K2M’s 3D-printed technologies, visit www.K2M.com. For more information about K2M’s Balance ACS platform, visit www.BACS.com.

About K2M

K2M Group Holdings, Inc. is a global leader of complex spine and minimally invasive solutions focused on achieving three-dimensional Total Body Balance. Since its inception, K2M has designed, developed, and commercialized innovative complex spine and minimally invasive spine technologies and techniques used by spine surgeons to treat some of the most complicated spinal pathologies. K2M has leveraged these core competencies into Balance ACS, a platform of products, services, and research to help surgeons achieve three-dimensional spinal balance across the axial, coronal, and sagittal planes, with the goal of supporting the full continuum of care to facilitate quality patient outcomes. The Balance ACS platform, in combination with the Company’s technologies, techniques, and leadership in the 3D-printing of spinal devices, enable K2M to compete favorably in the global spinal surgery market. For more information, visit www.K2M.com and connect with us on Facebook, Twitter, Instagram, LinkedIn, and YouTube.

Forward-Looking Statements

This press release contains forward-looking statements that reflect current views with respect to, among other things, operations and financial performance. Forward-looking statements include all statements that are not historical facts such as our statements about our expected financial results and guidance and our expectations for future business prospects. In some cases, you can identify these forward-looking statements by the use of words such as “outlook,” “guidance,” “believes,” “expects,” “potential,” “continues,” “may,” “will,” “should,” “could,” “seeks,” “predicts,” “intends,” “plans,” “estimates,” “anticipates” or the negative version of these words or other comparable words. Such forward-looking statements are subject to various risks and uncertainties including, among other things: our ability to achieve or sustain profitability in the future; our ability to demonstrate to spine surgeons the merits of our products; pricing pressures and our ability to compete effectively generally; collaboration and consolidation in hospital purchasing; in adequate coverage and reimbursement for our products from third-party payors; lack of long-term clinical data supporting the safety and efficacy of our products; dependence on a limited number of third-party suppliers; our ability to maintain and expand our network of direct sales employees, independent sales agencies and international distributors and their level of sales or distribution activity with respect to our products; proliferation of physician-owned distributorships in the industry; decline in the sale of certain key products; loss of key personnel; our ability to enhance our product offerings through research and development; our ability to manage expected growth; our ability to successfully acquire or invest in new or complementary businesses, products or technologies; our ability to educate surgeons on the safe and appropriate use of our products; costs associated with high levels of inventory; impairment of our goodwill and intangible assets; disruptions in our main facility or information technology systems; our ability to ship a sufficient number of our products to meet demand; our ability to strengthen our brand; fluctuations in insurance cost and availability; our ability to comply with extensive governmental regulation within the United States and foreign jurisdictions; our ability to maintain or obtain regulatory approvals and clearances within the United States and foreign jurisdictions; voluntary corrective actions by us or our distribution or other business partners or agency enforcement actions; recalls or serious safety issues with our products; enforcement actions by regulatory agencies for improper marketing or promotion; misuse or off-label use of our products; delays or failures in clinical trials and results of clinical trials; legal restrictions on our procurement, use, processing, manufacturing or distribution of allograft bone tissue; negative publicity concerning methods of tissue recovery and screening of donor tissue; costs and liabilities relating to environmental laws and regulations; our failure or the failure of our agents to comply with fraud and abuse laws; U.S. legislative or Food and Drug Administration regulatory reforms; adverse effects of medical device tax provisions; potential tax changes in jurisdictions in which we conduct business; our ability to generate significant sales; potential fluctuations in sales volumes and our results of operations over the course of the year; uncertainty in future capital needs and availability of capital to meet our needs; our level of indebtedness and the availability of borrowings under our credit facility; restrictive covenants and the impact of other provisions in the indenture governing our convertible senior notes and our credit facility; continuing worldwide economic instability; our ability to protect our intellectual property rights; patent litigation and product liability lawsuits; damages relating to trade secrets or non-competition or non-solicitation agreements; risks associated with operating internationally; fluctuations in foreign currency exchange rates; our ability to comply with the Foreign Corrupt Practices Act and similar laws; increased costs and additional regulations and requirements as a result of being a public company; our ability to implement and maintain effective internal control over financial reporting; our lack of current plans to pay cash dividends; our ability to take advantage of certain reduced disclosure requirements and exemptions as a result of being an emerging growth company; potential dilution by the future issuances of additional common stock in connection with our incentive plans, acquisitions or otherwise; anti-takeover provisions in our organizational documents and our ability to issue preferred stock without shareholder approval; potential limits on our ability to use our net operating loss carryforwards; and other risks and uncertainties, including those described under the section entitled “Risk Factors” in our most recent Annual Report on Form 10-K filed with the SEC, as such factors may be updated from time to time in our periodic filings with the SEC, which are accessible on the SEC’s website at www.sec.gov. Accordingly, there are or will be important factors that could cause actual outcomes or results to differ materially from those indicated in these statements. These factors should not be construed as exhaustive and should be read in conjunction with the other cautionary statements that are included in this release and our filings with the SEC.

We operate in a very competitive and challenging environment. New risks and uncertainties emerge from time to time, and it is not possible for us to predict all risks and uncertainties that could have an impact on the forward-looking statements contained in this release. We cannot assure you that the results, events and circumstances reflected in the forward-looking statements will be achieved or occur, and actual results, events or circumstances could differ materially from those described in the forward-looking statements.

The forward-looking statements made in this press release relate only to events as of the date on which the statements are made. We undertake no obligation to publicly update or review any forward-looking statement, whether as a result of new information, future developments or otherwise, except as required by law. We may not actually achieve the plans, intentions or expectations disclosed in our forward-looking statements and you should not place undue reliance on our forward-looking statements. Unless specifically stated otherwise, our forward-looking statements do not reflect the potential impact of any future acquisitions, mergers, dispositions, joint ventures, investments or other strategic transactions we may make.

Media Contact:

Zeno Group on behalf of K2M Group Holdings, Inc.

Christian Emering, 212-299-8985

Christian.Emering@ZenoGroup.com

Investor Contact:

Westwicke Partners on behalf of K2M Group Holdings, Inc.

Mike Piccinino, CFA, 443-213-0500

K2M@westwicke.com