LEESBURG, Va., Oct. 26, 2016 (GLOBE NEWSWIRE) — K2M Group Holdings, Inc. (NASDAQ:KTWO) (the “Company” or “K2M”), a global medical device company focused on designing, developing and commercializing innovative and proprietary complex spine and minimally invasive spine technologies and techniques, today announced the U.S. launch of its award-winning CASCADIA™ Interbody Systems, featuring Lamellar 3D Titanium Technology™, during the 31st North American Spine Society (NASS) Annual Meeting, Oct. 26-29, 2016, in Boston at Booth #1615.

K2M will present clinical background on its 3D-printed technologies and showcase the Company’s comprehensive CASCADIA product portfolio, which was recognized by Orthopedics This Week with a 2016 Spine Technology Award as one of the best new spine technologies of 2016. K2M will also highlight 3D printing manufacturing techniques by featuring a state-of-the-art 3D printer and a spatially immersive virtual reality experience at its NASS booth. The U.S. launch of K2M’s comprehensive 3D solutions, combined with an enhanced presence at NASS, further reinforces K2M’s standing as the global market-leading innovator and provider of 3D-printed spinal implants.

K2M’s Market-Leading Portfolio of Innovative 3D-Printed CASCADIA Implants

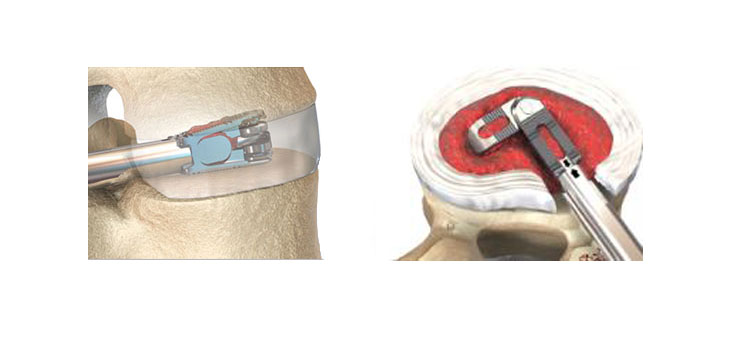

K2M’s comprehensive CASCADIA product portfolio includes the CASCADIA TL, AN, Lateral, AN Lordotic Oblique, and Cervical Interbody Systems. K2M’s CASCADIA Interbody Systems feature the Company’s innovative Lamellar 3D Titanium Technology, which uses an advanced 3D printing method to create structures that are impossible with traditional manufacturing techniques. Starting with a titanium powder, the CASCADIA implants are grown through the selective application of a high-energy laser beam, incorporating complex internal geometries and rough surface architecture that pre-clinical data have associated with bone growth activity. K2M’s CASCADIA implants utilize this technology to create a 70% porous implant with an increased bone graft volume and similar stiffness when compared to equivalent K2M PEEK designs.

“With over a year of usage experience across multiple CASCADIA interbody platforms, I continue to be impressed with the Lamellar 3D Titanium Technology,” stated Tom Morrison, MD, a neurosurgeon at Polaris Spine & Neurosurgery Center in Atlanta, Georgia. “The porosity and surface roughness properties make great biologic sense and the long term follow up I’m seeing with my patients reinforces my good impression. I look forward to continuing use of the CASCADIA Interbody Systems and am excited to further incorporate K2M’s Lamellar 3D Titanium Technology in my practice through future developments in other bone-growth applications.”

The CASCADIA interbodies and instrumentation facilitate intraoperative efficiency in the restoration of proper disc height and sagittal balance in skeletally mature patients. Together, these systems offer comprehensive solutions for both lumbar and cervical interbody fusion procedures used in treating patients for degenerative disc disease, degenerative scoliosis, and other spinal deformities in skeletally mature patients. The CASCADIA Interbody Systems include a full range of implant sizes carefully designed to accommodate the vertebral anatomy.

“We are excited to announce the U.S. launch of our 3D-printed CASCADIA Interbody Systems—featuring Lamellar 3D Titanium Technology—at this year’s NASS annual meeting, furthering our leadership position in offering comprehensive 3D solutions,” stated K2M President and CEO Eric Major. “We believe our success in the 3D-printed spine technology space over the last year represents another strong example of our ability to leverage our differentiated R&D capabilities to introduce new and innovative products. Since debuting Lamellar 3D Titanium Technology and CASCADIA at last year’s NASS meeting, K2M has established a leadership position in this innovative and rapidly growing area of the spinal device industry, as evidenced by our growing portfolio of FDA-cleared, 3D-printed interbodies—the most comprehensive portfolio in the market. We are committed to advancing this leadership position with continued innovation and commercialization of our advanced 3D-printed technologies around the world.”

K2M to Showcase Market-Leading 3D-Printed CASCADIA Portfolio at NASS 2016 through Clinical Presentations, Product & Advanced Printing Demonstrations, & Virtual Reality Experiences

K2M will highlight its 3D-printed technologies at Booth #1615 and in two clinical presentations during NASS.

- K2M Inc.: 3D Printed Lamellar Titanium Interbody

John P. Kostuik, MD; Thomas J. Morrison III, MD; Jennifer A. Moore; Dave Fiorella

Innovative Technology Presentation: Wednesday, October 26, 5:25-5:30 p.m.; Room 210ABC

- Lamellar 3D Titanium & Advances in Interbody Fusion Technologies

Paul Saiz, MD

Thursday, October 27, 5:30-7:30 p.m.; Morton’s Boston Seaport Winter Garden Atrium

K2M will display a ProX DMP 320 Direct Metal Printer from 3D Systems, a production-level metal printer that is used to manufacture the CASCADIA interbodies. The direct-metal printing method uses a laser beam to selectively fuse titanium powder in a layer-by-layer fashion to create three-dimensional shapes. The 3D printer will showcase how additive manufacturing technology has enabled K2M to create incredibly complex geometries designed specifically for bony integration that would have been highly impractical to create through traditional, subtractive machining methods.

To further highlight 3D printing manufacturing techniques, K2M will offer a virtual reality opportunity for booth attendees to experience a spatially immersive simulation to visualize how the CASCADIA implants are printed using advanced additive manufacturing techniques.

Major added, “We are very excited to participate at NASS, an important event for our industry each year, and even more important for K2M in 2016. This event represents a unique opportunity for our Company to showcase both our innovative Lamellar 3D Titanium Technology, and our comprehensive 3D-printed product portfolio, to provide attendees with a better understanding of what is driving the strong market response to date within the clinician community through clinical presentations, 3D printing demonstrations, and a virtual reality experience.”

For more information on Lamellar 3D Titanium Technology, the CASCADIA Interbody Systems, and K2M’s complete product portfolio, visit www.K2M.com.

About K2M

K2M Group Holdings, Inc. is a global medical device company focused on designing, developing and commercializing innovative complex spine and minimally invasive spine technologies and techniques used by spine surgeons to treat some of the most difficult and challenging spinal pathologies. K2M has leveraged these core competencies to bring to market an increasing number of products for patients suffering from degenerative spinal conditions. These technologies and techniques, in combination with a robust product pipeline, enable the Company to favorably compete in the global spinal surgery market. Additional information is available online at www.K2M.com.

Find K2M on Facebook: https://www.facebook.com/K2MInc

Follow K2M on Twitter: http://twitter.com/K2MInc

Watch K2M on YouTube: http://www.youtube.com/user/K2MInc

Forward-Looking Statements

This press release contains forward-looking statements that reflect current views with respect to, among other things, operations and financial performance. Forward-looking statements include all statements that are not historical facts such as our statements about our expected financial results and guidance and our expectations for future business prospects, including with respect to our international distribution partners in Australia and Japan. In some cases, you can identify these forward-looking statements by the use of words such as “outlook,” “guidance,” “believes,” “expects,” “potential,” “continues,” “may,” “will,” “should,” “could,” “seeks,” “predicts,” “intends,” “plans,” “estimates,” “anticipates” or the negative version of these words or other comparable words. Such forward-looking statements are subject to various risks and uncertainties including, among other things: our ability to achieve or sustain profitability; our ability to successfully demonstrate the merits of our technologies and techniques; pricing pressure from our competitors, hospitals and changes in third-party coverage and reimbursement; competition and our ability to develop and commercialize new products; the greater resources available to some of our competitors; aggregation of hospital purchasing from collaboration and consolidation; hospitals and other healthcare providers may be unable to obtain adequate coverage and reimbursement for procedures performed using our products; the safety and efficacy of our products is not yet supported by long-term clinical data; our dependence on a limited number of third-party suppliers; our ability to maintain and expand our network of direct sales employees, independent sales agencies and international distributors and their level of sales or distribution activity with respect our products; the proliferation of physician-owned distributorships; concentration of sales from a limited number of spinal systems or products that incorporate these technologies; loss of the services of key members of our senior management, consultants or personnel; ability to enhance our product offerings through our research and development efforts; failure to properly manage our anticipated growth; acquisitions of or investments in new or complementary businesses, products or technologies; ability to train surgeons on the safe and appropriate use of our products; requirements to maintain high levels of inventory; impairment of our goodwill or intangible assets; disruptions in our information technology systems; any disruption or delays in operations at our facilities, including our new headquarters facility; our ability to ship a sufficient number of our products to meet demand; ability to strengthen our brand; fluctuations in insurance cost and availability; extensive governmental regulation including by the FDA; in the United States and foreign jurisdictions; failure to obtain or maintain regulatory approvals and FDA clearances; requirements for new 510(k) clearances, premarket approvals or new or amended CE Certificates of Conformity; medical device reporting regulations in the United States and foreign jurisdictions; voluntary corrective actions by us or our distribution or other business partners or agency enforcement actions; a recall of our products; withdrawal or restrictions on our products or the discovery of serious safety issues with our products; possible enforcement action if we engage in improper marketing or promotion of our products; the misuse or off-label use of our products; delays or failures in any future clinical trials; our reliance on the performance of third parties who assist us in clinical trials and pre-clinical development; the results of clinical trials; procurement and use of allograft bone tissue; environmental laws and regulations; compliance by us or our sales representatives with FDA regulations or fraud and abuse laws; U.S. legislative or regulatory healthcare reforms; medical device tax provisions in the healthcare reform laws; our need to generate significant sales to become profitable; potential fluctuations in sales volumes and our results of operations over the course of the year; uncertainty in our future capital needs; failure to comply with restrictions in our revolving credit facility; continuing worldwide economic instability; our inability to protect our intellectual property rights; our reliance on patent rights that we either license from others or have obtained through assignments; our patent litigation; the outcome of potential claims that we, our employees, our independent sales agencies or our distributors have wrongfully used or disclosed alleged trade secrets or are in breach of non-competition or non-solicitation agreements with our competitors; potential product liability lawsuits; operating risks relating to our international operations; foreign currency fluctuations; our ability to comply with the Foreign Corrupt Practices Act and similar laws associated with our activities outside the United States; possible conflicts of interest with our large shareholders; increased costs and additional regulations and requirements as a result of becoming a public company; our ability to implement and maintain effective internal control over financial reporting in the future; volatility in our common stock; our current plans not to pay dividends; potential dilution due to our issuance of common stock under our incentive plans, for acquisitions or otherwise; the amount of common stock held by our pre-IPO owners; the impact of anti-takeover provisions in our organizational documents and under Delaware law; our status as an emerging growth company, our ability to use our net operating loss carryforwards; the potential impact of any future acquisitions, mergers, dispositions, joint ventures, investments or other strategic transactions we may make; and other risks and uncertainties, including those described under the section entitled “Risk Factors” in our most recent Annual Report on Form 10-K filed with the SEC, as such factors may be updated from time to time in our periodic filings with the SEC, which are accessible on the SEC’s website at www.sec.gov. Accordingly, there are or will be important factors that could cause actual outcomes or results to differ materially from those indicated in these statements. These factors should not be construed as exhaustive and should be read in conjunction with the other cautionary statements that are included in this release and our filings with the SEC.

We operate in a very competitive and challenging environment. New risks and uncertainties emerge from time to time, and it is not possible for us to predict all risks and uncertainties that could have an impact on the forward-looking statements contained in this release. We cannot assure you that the results, events and circumstances reflected in the forward-looking statements will be achieved or occur, and actual results, events or circumstances could differ materially from those described in the forward-looking statements.

The forward-looking statements made in this press release relate only to events as of the date on which the statements are made. We undertake no obligation to publicly update or review any forward-looking statement, whether as a result of new information, future developments or otherwise, except as required by law. We may not actually achieve the plans, intentions or expectations disclosed in our forward-looking statements and you should not place undue reliance on our forward-looking statements.

Media Contact:

Zeno Group on behalf of K2M Group Holdings, Inc.

Christian Emering, 212-299-8985

Christian.Emering@ZenoGroup.com

Investor Contact:

Westwicke Partners on behalf of K2M Group Holdings, Inc.

Mike Piccinino, CFA, 443-213-0500

K2M@westwicke.com