Smith & Nephew (LSE:SN, NYSE:SNN), the global medical technology business, and the University of Hull today announce a long-term collaboration driving research into pioneering approaches to advanced wound care.

The partnership will create one of the world’s largest Wound Care Research Clusters, combining world-leading academia and industry with the aim of developing scientific insights and innovative treatments for advanced wound care.

A five year framework has been established which sees a co-investment of around £3 million. Within this, eight multi-disciplinary PhD studentships have been created.

Dr David Richards, Pro-Vice Chancellor for Research and Enterprise at the University of Hull, said: “This partnership goes to further strengthen our links with industry at the same time as creating a global hub for pioneering new approaches in this field. By combining the considerable expertise we have at the University with those at Smith & Nephew, we will drive research which will help to position ourselves as global leaders in this field.”

Dr Matthew Hardman, Wound Healing Research Group Head, University of Hull, said: “I am delighted by the establishment of this exciting new multi-disciplinary wound care cluster. This venture brings together a team of experts from across the University and builds upon our existing links with a world-leader in advanced wound management. This exciting partnership will ultimately deliver significant patient benefits.”

The collaboration has been welcomed by new local MP Emma Hardy, who commented: “Britain is a global leader in medical technology innovation. Partnerships such as this between Smith & Nephew and University of Hullfurther strengthen our position at the forefront of global medical research and development. Creating one of the largest wound care clusters in the world is a huge vote of confidence in the UK as a whole and Hull in particular, as we build a ‘global Britain’ with pioneering medical technology at its heart.”

Supporting the collaboration is Smith & Nephew’s new state-of-the-art Research & Development (R&D) centre in Hull, UK, and the University of Hull’s £28-million new Health Campus, due to open in the summer. Smith & Nephew’s R&D hub for wound management technologies, which opened on 12 May, specialises in toxicology, chemistry and microbiology among other specialist fields. Smith & Nephew’s Hull site also manufactures some of the world’s most advanced wound care products, including pioneering products such as PICO◊, a unique single use negative pressure wound therapy system and ALLEVYN◊ Life advanced foam dressings.

The University of Hull’s new Health Campus is due to open in July this year. At its heart is the Allam Medical Building which will house the University’s new Institute for Clinical and Applied Health Research and includes specialist biomedical and clinical research facilities, as well as a mock hospital ward, operating theatre and intensive care nursing facilities.

Smith & Nephew will extend the use of its facilities to the Wound Care Cluster PhD students through dedicated workshops and providing industrial placement supervisors. University of Hull alumni make up around 25% of staff within wound research and development at Smith & Nephew in Hull, with many more across different roles within the company.

Stewart McKinlay, Vice President of Research & Innovation, Smith & Nephew, said “We are thrilled that the University of Hull shares our passion for the importance of advancing the science of wound care. Pioneering innovation is a strategic priority for Smith & Nephew. This partnership will combine the brightest minds with the finest R&D facilities available with the aim of better supporting healthcare professionals in the advanced treatment of wounds, which is an area of significant unmet medical need and a substantial cost to healthcare systems.

“There will be opportunities for students and employees to interact on a daily basis to share knowledge, best practice and support our ambitious R&D pipeline. Combine that with the scale of scientific specialities that is based here, then this partnership is a truly exciting prospect.”

Enquiries

| Media Charles Reynolds Smith & Nephew

|

+44 (0) 1923 477314 |

| Ben Atwell / Matthew Cole FTI Strategic Consulting

|

+44 (0) 20 3727 1000 |

| Investors Ingeborg Oie Smith & Nephew |

+44 (0) 20 7401 7646 |

About Smith & Nephew

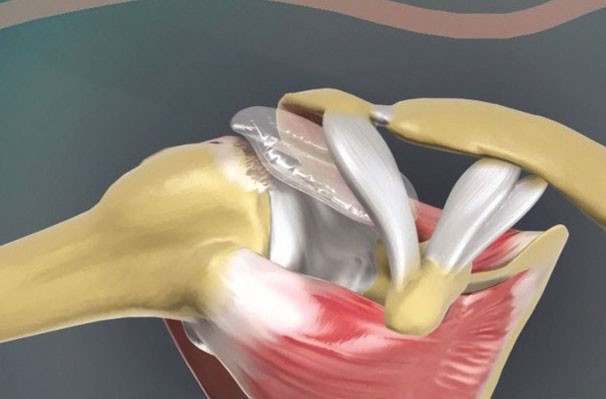

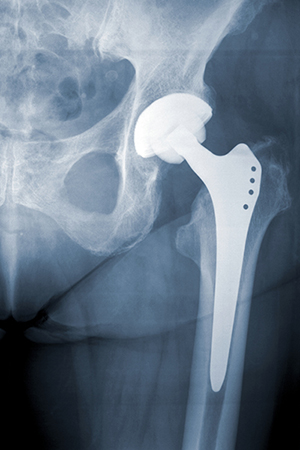

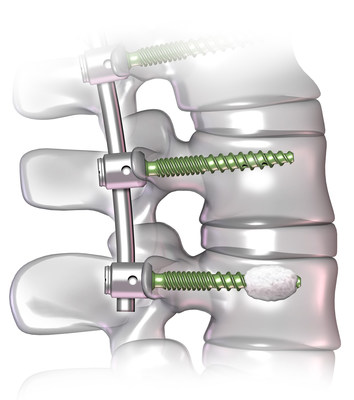

Smith & Nephew is a global medical technology business dedicated to helping healthcare professionals improve people’s lives. With leadership positions in Orthopaedic Reconstruction, Advanced Wound Management, Sports Medicine and Trauma & Extremities, Smith & Nephew has around 15,000 employees and a presence in more than 100 countries. Annual sales in 2016 were almost $4.7 billion. Smith & Nephew is a member of the FTSE100 (LSE:SN, NYSE:SNN).

For more information about Smith & Nephew, please visit our website www.smith-nephew.com, follow @SmithNephewplc on Twitter or visit SmithNephewplc on Facebook.com.

Forward-looking Statements

This document may contain forward-looking statements that may or may not prove accurate. For example, statements regarding expected revenue growth and trading margins, market trends and our product pipeline are forward-looking statements. Phrases such as “aim”, “plan”, “intend”, “anticipate”, “well-placed”, “believe”, “estimate”, “expect”, “target”, “consider” and similar expressions are generally intended to identify forward-looking statements. Forward-looking statements involve known and unknown risks, uncertainties and other important factors that could cause actual results to differ materially from what is expressed or implied by the statements. For Smith & Nephew, these factors include: economic and financial conditions in the markets we serve, especially those affecting health care providers, payers and customers; price levels for established and innovative medical devices; developments in medical technology; regulatory approvals, reimbursement decisions or other government actions; product defects or recalls or other problems with quality management systems or failure to comply with related regulations; litigation relating to patent or other claims; legal compliance risks and related investigative, remedial or enforcement actions; disruption to our supply chain or operations or those of our suppliers; competition for qualified personnel; strategic actions, including acquisitions and dispositions, our success in performing due diligence, valuing and integrating acquired businesses; disruption that may result from transactions or other changes we make in our business plans or organisation to adapt to market developments; and numerous other matters that affect us or our markets, including those of a political, economic, business, competitive or reputational nature. Please refer to the documents that Smith & Nephew has filed with the U.S. Securities and Exchange Commission under the U.S. Securities Exchange Act of 1934, as amended, including Smith & Nephew’s most recent annual report on Form 20-F, for a discussion of certain of these factors. Any forward-looking statement is based on information available to Smith & Nephew as of the date of the statement. All written or oral forward-looking statements attributable to Smith & Nephew are qualified by this caution. Smith & Nephew does not undertake any obligation to update or revise any forward-looking statement to reflect any change in circumstances or in Smith & Nephew’s expectations.

◊ Trademark of Smith & Nephew. Certain marks registered US Patent and Trademark Office.