CARLSBAD, Calif., Sept. 26, 2017 (GLOBE NEWSWIRE) — SeaSpine Holdings Corporation (NASDAQ:SPNE), a global medical technology company focused on surgical solutions for the treatment of spinal disorders, today announced the full commercial launch of the Shoreline Anterior Cervical Standalone (ACS) System, featuring TruProfile™ technology.

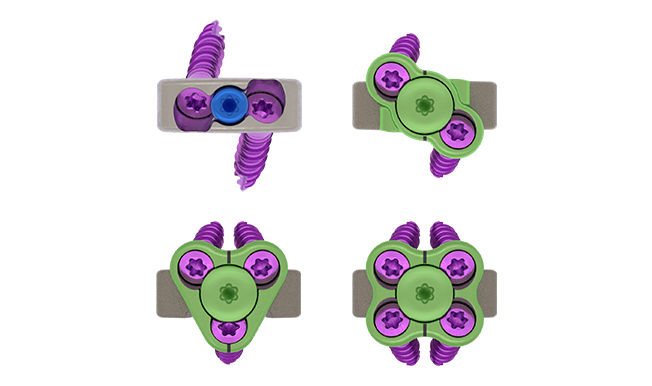

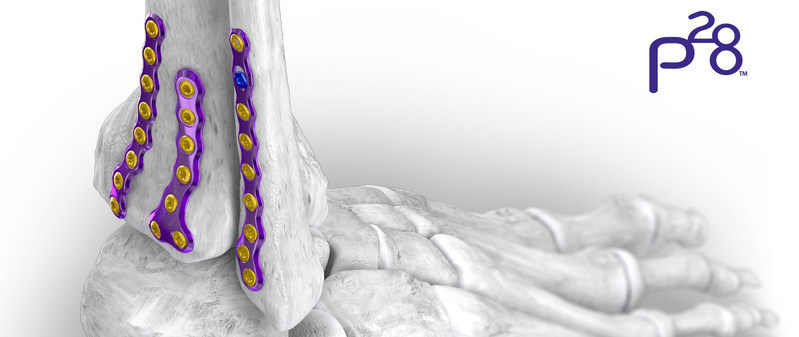

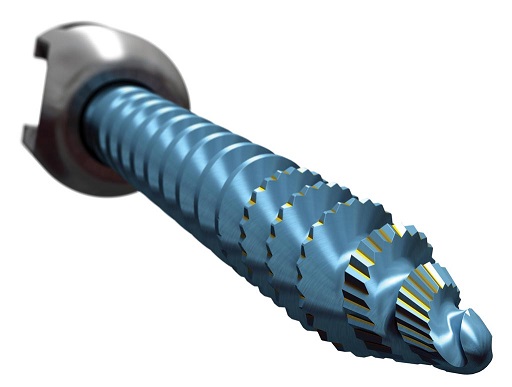

The Shoreline ACS System is designed to deliver maximum flexibility and modularity, offering zero- and low-profile plating options, including two, three and four hole variations, as well as 10 and 15 degree lordotic implants. This selection provides surgeons the ability to intraoperatively address a wide range of anatomy, surgical situations or bone. In addition, TruProfile technology offers a low profile plate design at 1.6mm thickness, minimizing the profile on the anterior aspect of the spine and minimizing cephalad caudal encroachment of adjacent segments.

“Shoreline with TruProfile has met the challenge of combining ease of implant placement and plate fixation to allow for a more responsive approach to specific patient requirements,” stated Dr. James Bruffey, an orthopedic surgeon in San Diego, CA.

All Shoreline interbody implants feature proprietary NanoMetalene surface technology designed to provide a bone-friendly titanium surface while retaining the benefits associated with traditional PEEK devices, such as biocompatibility, a modulus of elasticity like bone, and excellent radiographic visibility for post-operative imaging. NanoMetalene describes a sub-micron layer of commercially pure titanium molecularly bonded to a PEEK implant using a proprietary, high-energy, low-temperature process. Unlike other titanium coating applications, this process maximizes the implant surface area that has titanium nanotopography.

“The modular design of Shoreline with TruProfile is intended to optimize operating room efficiency and maximize procedural flexibility, while NanoMetalene provides the latest in surface technology,” stated Keith Valentine, President and Chief Executive Officer of SeaSpine. “In addition, we believe the hyperlordotic and large footprint offerings enable surgeons to assemble the best construct option to match patient anatomy.”

About SeaSpine

SeaSpine is a global medical technology company focused on the design, development and commercialization of surgical solutions for the treatment of patients suffering from spinal disorders. SeaSpine has a comprehensive portfolio of orthobiologics and spinal implant solutions to meet the varying combinations of products that neurosurgeons and orthopedic spine surgeons need to perform fusion procedures on the lumbar, thoracic and cervical spine. SeaSpine’s orthobiologics products consist of a broad range of advanced and traditional bone graft substitutes that are designed to improve bone fusion rates following a wide range of orthopedic surgeries, including spine, hip, and extremities procedures. SeaSpine’s spinal implant portfolio consists of an extensive line of products to facilitate spinal fusion in minimally invasive surgery (MIS), complex spine, deformity and degenerative procedures. Expertise in both orthobiologic sciences and spinal implant product development allows SeaSpine to offer its surgeon customers a differentiated portfolio and a complete solution to meet their fusion requirements. SeaSpine currently markets its products in the United States and in over 30 countries worldwide.

Forward-Looking Statements

SeaSpine cautions you that statements included in this news release that are not a description of historical facts are forward-looking statements that are based on the Company’s current expectations and assumptions. Such forward-looking statements may include, but are not limited to, statements relating to: the design and other benefits of the Shoreline ACS System, TruProfile technology, and NanoMetalene; the ability of the Shoreline ACS System to optimize operating room efficiency, maximize procedural flexibility, or enable surgeons to assemble the best construct option. Among the factors that could cause or contribute to material differences between our actual results and the expectations indicated by our forward-looking statements are risks and uncertainties that include, but are not limited to: the ability of newly launched products to perform as designed and intended and to meet the clinical needs of surgeons and patients; the limited clinical experience supporting the commercial launch of new products and the risk that such products may require substantial additional development activities, which could introduce unexpected expense and delay; the lack of long-term clinical data supporting the safety and efficacy of the Company’s products; and other risks and uncertainties more fully described in our news releases and periodic filings with the Securities and Exchange Commission. The Company’s public filings with the Securities and Exchange Commission are available at www.sec.gov.

You are cautioned not to place undue reliance on forward-looking statements, which speak only as of the date when made. SeaSpine does not intend to revise or update any forward-looking statement set forth in this news release to reflect events or circumstances arising after the date hereof, except as may be required by law.

Investor Relations Contact

Lynn Pieper

(415) 309-5999

ir@seaspine.com

SeaSpine Holdings Corporation