August 02, 2017

MEQUON, Wis.–(BUSINESS WIRE)–Titan Spine, a medical device surface technology company focused on developing innovative spinal interbody fusion implants, today announced that it continues its strong revenue acceleration for the second quarter of 2017, driven by the increasing demand for the Company’s nanoLOCK® surface technology. nanoLOCK® is the company’s next-generation surface technology featuring enhanced micro and nano-scaled architecture, proven to significantly improve the osteogenic response it creates.1

The company reports the following for the second quarter:

- Surpassed 50,000 implantations of its Endoskeleton® interbody fusion devices since inception

- nanoLOCK® sales volume has increased by 42% since the close of the first quarter

- nanoLOCK® has been utilized to date by 150 surgeons in 98 hospitals

- Achieved 2,500 implantations of nanoLOCK® since launch

Ted Bird, Chief Commercial Officer of Titan Spine, commented, “Following a record first quarter, we continued to exceed expectations during the second quarter for a strong close to the mid-2017 mark. The significant demand for nanoLOCK® is a direct reflection of our expanded sales team’s ability to reach more surgeons and surgeons’ recognition of the advantages our surface technology provides at the nano-cellular level for helping patients heal faster following spine fusion surgery. In fact, we have more than doubled the number of surgeon customers using nanoLOCK in the second quarter compared to the first. We are pleased that our second quarter achievements demonstrate a growing confidence and continued adoption of nanoLOCK®.”

Steve Cichy, Executive Vice President of Sales of Titan Spine, added, “The demand for nanoLOCK® has certainly fueled our significant sales growth over the first half of this year. We have recently invested significant capital to beef up our instrument set and implant inventory to meet this growing demand, which will start to pay dividends over the remainder of the year and beyond.”

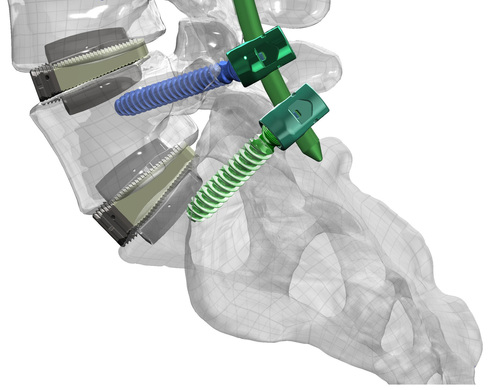

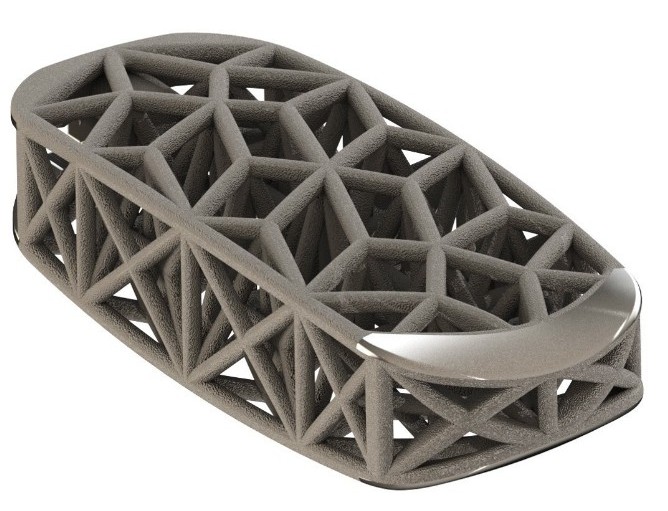

Titan Spine offers a full line of Endoskeleton® titanium implants that feature its proprietary nanoLOCK® surface technology, which was launched in the U.S. in October 2016 following FDA clearance in late 2014. The nanoLOCK® surface technology consists of a unique combination of roughened topographies at the macro, micro, and nano levels (MMN™). This unique combination of surface topographies is designed to create an optimal host-bone response and actively participate in the fusion process by promoting the upregulation of osteogenic and angiogenic factors necessary for bone growth, encouraging natural production of bone morphogenetic proteins (BMPs), downregulating inflammatory factors, and creating the potential for a faster and more robust fusion.2,3,4 All Endoskeleton® devices are covered by the company’s risk share warranty.

About Titan Spine

Titan Spine, LLC is a surface technology company focused on the design and manufacture of interbody fusion devices for the spine. The company is committed to advancing the science of surface engineering to enhance the treatment of various pathologies of the spine that require fusion. Titan Spine, located in Mequon, Wisconsin and Laichingen, Germany, markets a full line of Endoskeleton® interbody devices featuring its proprietary textured surface in the U.S. and portions of Europe through its sales force and a network of independent distributors. To learn more, visit www.titanspine.com.

nanoLOCK® named the winner of Back Pain Centers of America’s 2017 Awards of Excellence for the Technology Innovation Award

1 Olivares-Navarrete, R., Hyzy S.L., Gittens, R.A., Berg, M.E., Schneider, J.M., Hotchkiss, K., Schwartz, Z., Boyan, B. D. Osteoblast lineage cells can discriminate microscale topographic features on titanium-aluminum-vanadium surfaces. Ann Biomed Eng. 2014 Dec; 42 (12): 2551-61.

2 Olivares-Navarrete, R., Hyzy, S.L., Slosar, P.J., Schneider, J.M., Schwartz, Z., and Boyan, B.D. (2015). Implant materials generate different peri-implant inflammatory factors: PEEK promotes fibrosis and micro-textured titanium promotes osteogenic factors. Spine, Volume 40, Issue 6, 399–404.

3 Olivares-Navarrete, R., Gittens, R.A., Schneider, J.M., Hyzy, S.L., Haithcock, D.A., Ullrich, P.F., Schwartz, Z., Boyan, B.D. (2012). Osteoblasts exhibit a more differentiated phenotype and increased bone morphogenetic production on titanium alloy substrates than poly-ether-ether-ketone. The Spine Journal, 12, 265-272.

4 Olivares-Navarrete, R., Hyzy, S.L., Gittens, R.A., Schneider, J.M., Haithcock, D.A., Ullrich, P.F., Slosar, P. J., Schwartz, Z., Boyan, B.D. (2013). Rough titanium alloys regulate osteoblast production of angiogenic factors. The Spine Journal, 13, 1563-1570.

Contacts

Company:

Titan Spine

Andrew Shepherd, 866-822-7800

ashepherd@titanspine.com

or

Media:

The Ruth Group

Kirsten Thomas, 508-280-6592

kthomas@theruthgroup.com