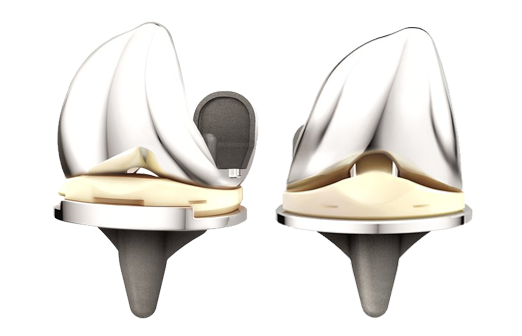

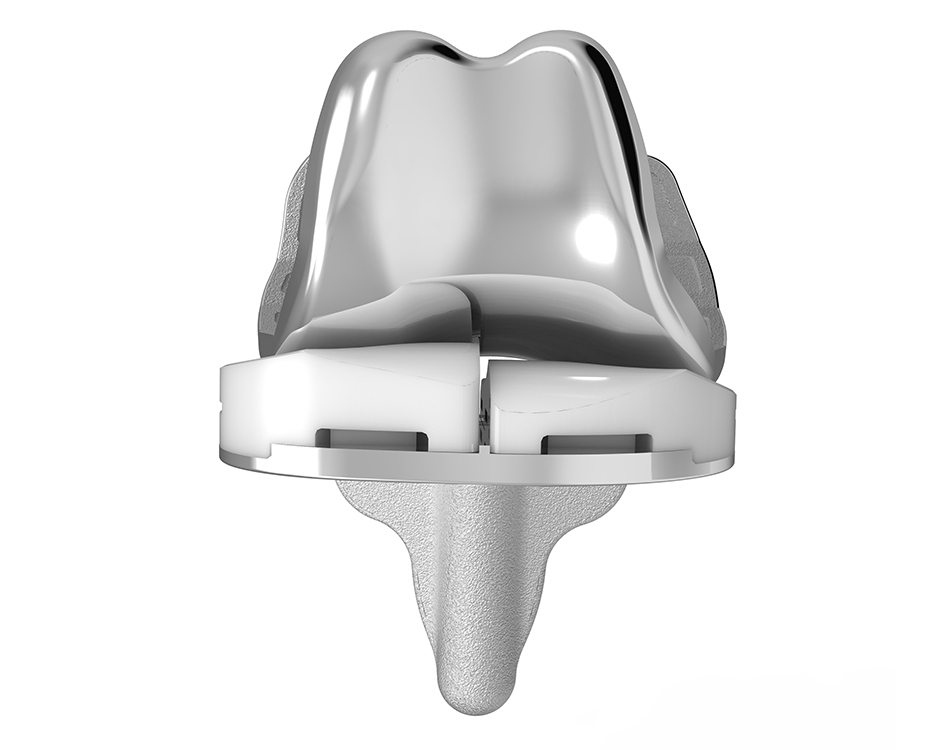

BILLERICA, Mass., June 13, 2017 (GLOBE NEWSWIRE) — ConforMIS, Inc. (NASDAQ:CFMS), a medical technology company that offers joint replacement implants customized to fit each patient’s unique anatomy, today announced the publication of a retrospective study comparing adverse events rates and cost of care for total knee arthroplasty (TKA) patients treated with either customized individually made (CIM) implants or standard off-the-shelf (OTS) implants. Results were published in the peer-reviewed journal Arthroplasty Today on June 8, 2017.

According to the study results, a smaller percentage of TKA patients treated with customized implants experienced adverse events at both discharge (3.3% vs OTS 14.1%; P = .003) and 90 days after discharge (8.1% vs OTS 18.2%; P = .023). A greater proportion of patients who received customized implants were discharged in less than 3 days (42.1% vs OTS 30.3%; P = .037). In addition, a smaller percentage of patients treated with customized implants (4.8% vs OTS 16.4%; P = .003) were discharged to a rehabilitation center or other post-acute care facility. Further, fewer patients treated with customized implants (2.4% vs OTS 11.6%; P = .005) required blood a transfusion.

Furthermore, the total average real hospital costs between the CIM and OTS groups were nearly identical (customized implant $16,192 vs OTS $16,240; P = .913), suggesting that patients with customized implants received improved hospital outcomes at no additional cost to the hospital. However, risk-adjusted per patient total cost of care showed a net savings of $913.87 (P = .240) per patient for the customized implant group for bundle of care, including the preoperative computed tomography scan, TKA hospitalization, and discharge disposition. Follow-up care costs demonstrated a savings of $1,313 (customized implant $5,048 vs OTS $6,361; P = .007).

“Our results in this single-site population of patients illustrate that treatment with a customized implant led to significantly lower transfusion rates, fewer adverse events and reduced need for discharge to a rehabilitation facility or post-acute care facility,” said Steven Culler, PhD, a healthcare economist at Emory University. “We also found that improved outcomes among patients treated with customized implants were achieved without increasing overall costs and that post-discharge costs were significantly lower among patients treated with customized implants.”

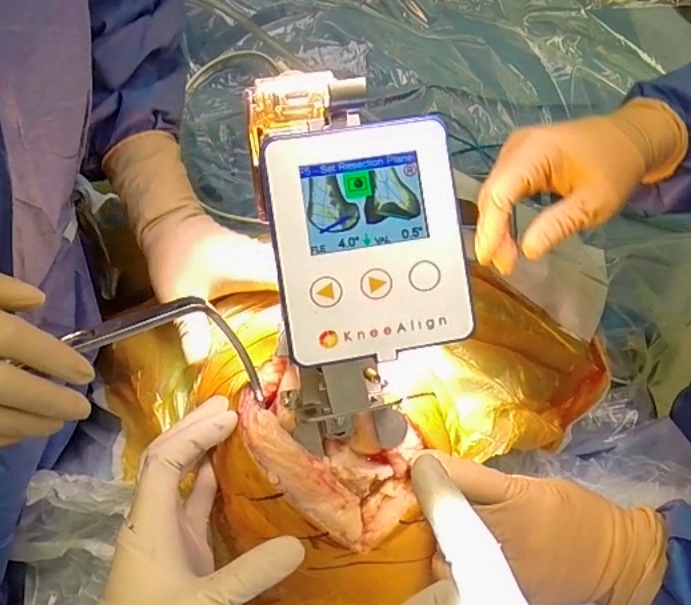

In this study, which was financially supported by ConforMIS, researchers completed a retrospective review of outcomes and costs for 248 consecutive TKA patients treated at a single institution and by the same surgeon. All surgeries occurred between April 1, 2010, and November 11, 2013 based on consistent intraoperative protocols. Patients received either a customized knee implant (designed and developed based on their unique anatomy (n=126)) or an OTS implant selected from a range of pre-manufactured sizes (n=122). Study data were collected from patients’ medical record or the hospital’s administrative billing record.

When controlling for gender, age, body mass index (BMI) and selected comorbid conditions, patients in the OTS arm were 5.5 times more likely to be discharged to a rehab or post-acute care facility. Patients treated with OTS implants were also 4.6 times more likely to require blood transfusion and 4.4 times more likely to experience an adverse event.

“This study provides compelling data indicating that patients treated with customized total knee implants achieve better outcomes on several important measures without increasing real hospital costs and while reducing the average total cost of the episode of care and the average cost of follow-up care,” said Mark Augusti, Chief Executive Officer and President of ConforMIS. “These findings further demonstrate the benefits of customized total knee implants technology to patients, surgeons, hospitals and payers. Additionally, they are part of an important and changing conversation about the role of total knee implants in the delivery of better outcomes at lower costs – a conversation that we are committed to pursuing.”

About ConforMIS, Inc.

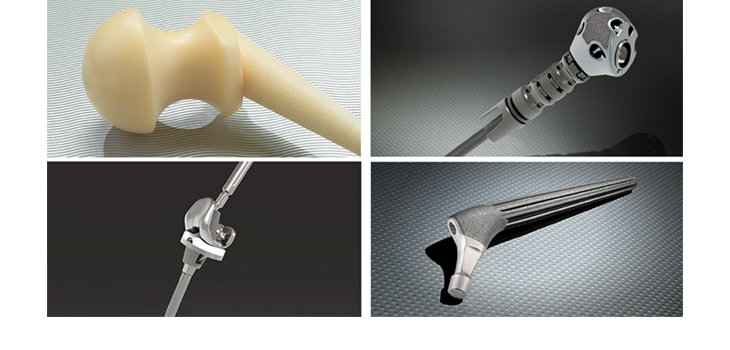

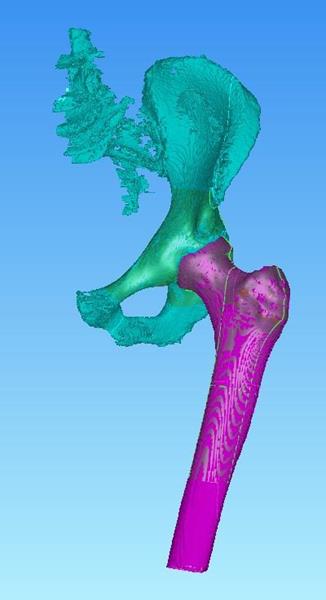

ConforMIS is a medical technology company that uses its proprietary iFit Image-to-Implant technology platform to develop, manufacture and sell joint replacement implants that are individually sized and shaped, or customized, to fit each patient’s unique anatomy. ConforMIS offers a broad line of customized knee implants and pre-sterilized, single-use instruments delivered in a single package to the hospital. In clinical studies, ConforMIS iTotal CR demonstrated superior clinical outcomes, including better function and greater patient satisfaction, compared to traditional, off-the-shelf implants. ConforMIS owns or exclusively in-licenses approximately 450 issued patents and pending patent applications that cover customized implants and patient-specific instrumentation for all major joints.

For more information, visit www.conformis.com. To receive future releases in e-mail alerts, sign up at http://ir.conformis.com/.

Cautionary Statement Regarding Forward-Looking Statements

Any statements in this press release about future expectations, plans and prospects for ConforMIS, including statements about ConforMIS’ clinical strategy, the potential clinical, economic or other impacts and advantages of using customized implants, the changing view of CIM v. OTS implants, as well as other statements containing the words “anticipate,” “believe,” “continue,” “could,” “estimate,” “expect,” “intend,” “may,” “might,” “plan,” “potential,” “predict,” “project,” “should,” “target,” “will,” or “would” and similar expressions, constitute forward-looking statements within the meaning of the safe harbor provisions of The Private Securities Litigation Reform Act of 1995. We may not actually achieve the plans, intentions or expectations disclosed in our forward-looking statements, and you should not place undue reliance on our forward-looking statements. Actual results or events could differ materially from the plans, intentions and expectations disclosed in the forward-looking statements we make as a result of a variety of risks and uncertainties, including risks related to our clinical studies and the other risks and uncertainties described in the “Risk Factors” sections of our public filings with the Securities and Exchange Commission. In addition, the forward-looking statements included in this press release represent ConforMIS’s views as of the date hereof. ConforMIS anticipates that subsequent events and developments may cause ConforMIS’s views to change. However, while ConforMIS may elect to update these forward-looking statements at some point in the future, ConforMIS specifically disclaims any obligation to do so. These forward-looking statements should not be relied upon as representing ConforMIS’s views as of any date subsequent to the date hereof.

CONTACT:

Media contacts:

Bill Berry

Berry & Company Public Relations

Bberry@berrypr.com

(212) 253-8881

Lynn Granito

Berry & Company Public Relations

Lgranito@berrypr.com

(212) 253-8881

Investor contact

Oksana Bradley

ir@conformis.com

(781) 374-5598