ALISO VIEJO, CA (PRWEB) OCTOBER 03, 2017

OrthAlign, Inc., a privately held U.S.-based medical device and technology company, received CE Mark Approval to market its advanced precision technologies for Direct Anterior Approach Total Hip (DAA HipAlign®) and Unicompartmental Knee Arthroplasty (UniAlign®) surgeries, in Europe and other countries.

“As OrthAlign has focused on expanding customer reach and its application pipeline in 2017, we are pleased that surgeons outside of the United States and Japan can now have access to our newest precision technologies DAA HipAlign and UniAlign,” said Eric B. Timko, OrthAlign’s Chief Executive Officer and Chairman. “We will continue providing orthopedic surgeons and healthcare facilities throughout the world our clinically beneficial portfolio of products, staying true to our core design principles of ease of use, precision, and cost effectiveness.”

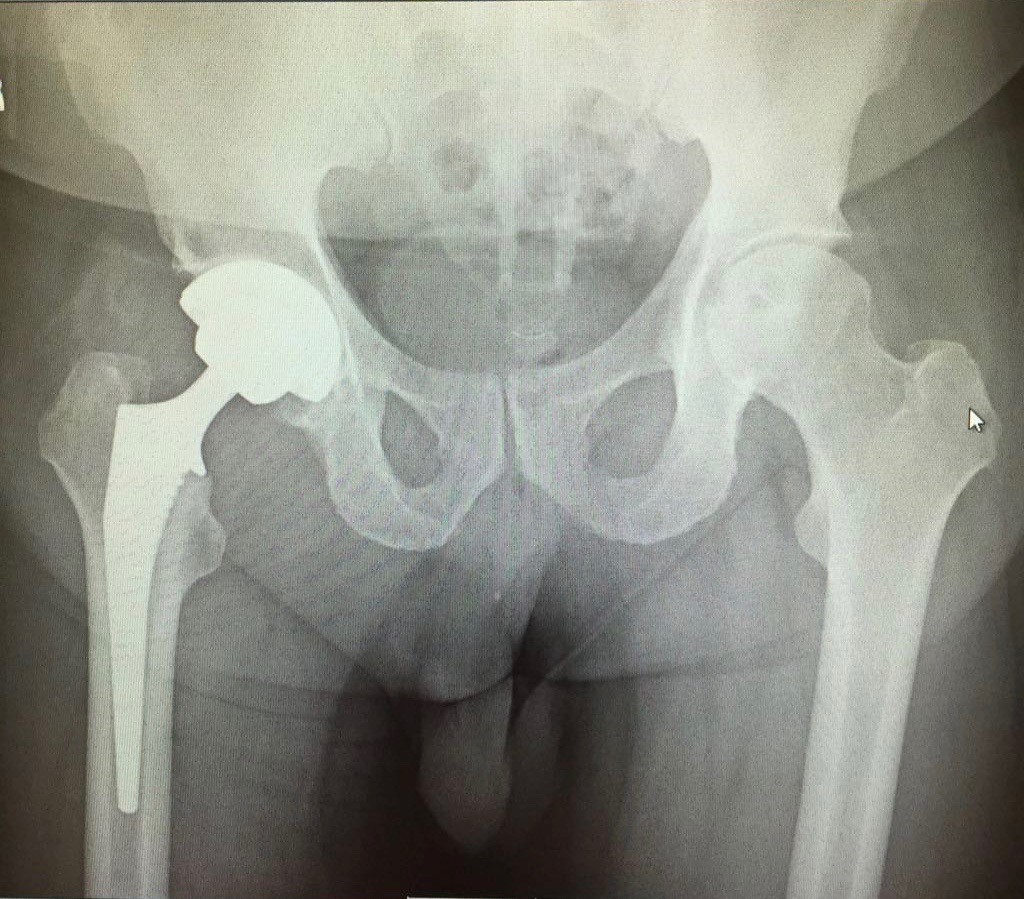

Recent global statistics have shown that the direct anterior approach for total hip arthroplasty is growing, as it arguably leads to quicker recovery, less pain, and more normal function for patients after hip replacement. DAA HipAlign does not require any pre-operative imaging or intraoperative fluoroscopy, while providing more clinically relevant positioning for cup placement and leg length measurement. Early clinical data from the United States demonstrates that surgeons can expect to reduce fluoroscopy exposure time by about 45%. Early clinical data from Japan shows cup placement (for both inclination and anteversion) accuracy of ±10°, with at least 95.9% confidence.

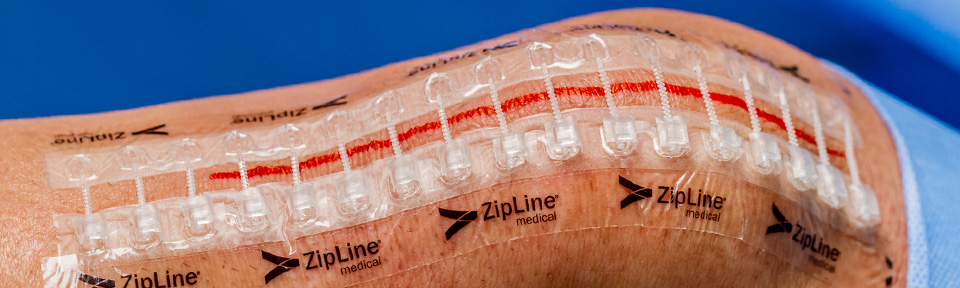

Unicompartmental knee arthroplasty procedures are also growing in popularity, worldwide. UniAlign establishes the mechanical axis of the tibia, determining the varus/valgus angle and the posterior slope angle of the cutting block relative to the tibia, for the transverse resection. The system has been validated in simulated use testing to achieve resection accuracy of ±2.0° in the coronal plane, ±3.0° in the sagittal plane and ±2.0 mm in depth. This accuracy has been validated with at least 90% confidence.

“As international expansion has been one of OrthAlign’s priorities, receiving CE Mark approvals for use of our technology in two rapidly growing segments is great news,” said James Young Kim, OrthAlign’s Vice President and General Manager of International. “Our international distributor network has been waiting for these approvals, as many of their local surgeons have been asking for the technology.”

DAA HipAlign and UniAlign will be included in OrthAlign Plus® handheld navigation devices, along with OrthAlign’s award-winning KneeAlign® technology. To date, OrthAlign technology has successfully been used in over 65,000 cases, in over 25 countries, with more than 15 published international clinical studies demonstrating its accuracy.

About OrthAlign, Inc.

OrthAlign is a privately held medical device and technology company, developing advanced technologies that deliver healthier and more pain-free lifestyles to joint replacement patients, globally. We provide healthcare professionals with cutting edge, computer-assisted surgical tools that seamlessly and cost-effectively deliver vital data and clinical results to optimize outcomes for our patients. For more information regarding OrthAlign, please visit http://www.orthalign.com.

“ORTHALIGN®, ORTHALIGN PLUS®, KNEEALIGN®, KNEEALIGN® 2, HIPALIGN®, and UNIALIGN™ are registered trademarks of OrthAlign, Inc.”